If you are assigned in securing or purchasing of rupture discs, you must understand the basics so you can choose wisely. If you already know things about rupture discs, it won’t hurt to refresh your knowledge.

Keep in mind that rupture discs are next to safety valves. This means that its importance should never be underestimated. In the end, it can protect pipelines and vessels from deformation and other damages. Here is a simple refresher to help you secure the right rupture discs according to your industry needs:

What is a rupture disc?

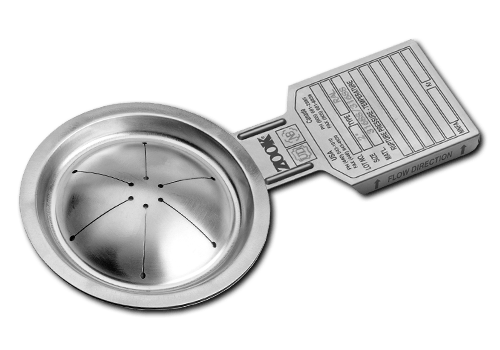

A rupture disc is a type of pressure-relief component. It is widely used by industrial plants to protect pipelines and vessels from damage. The main objective of a rupture disc is to minimize system downtime. Rupture discs take the form of dome or flat surface with one or more layers.

How does it work?

Rupture discs are safety devices installed in the piping, vessel and other pressure-containing components. It is designed with a defined breaking point that responds to a specific pressure. It is installed in flanges or it is already soldered into the holder. There are signaling options that you can consider to notify you immediately when triggering or opening of rupture discs happen.

Once the rupture disc is burst out, the entire system pressure will be released. With the release of pressure, the system can resume its function. However, you need to replace the burst rupture disc to be successful. Keep in mind that as soon as the rupture disc bursts out, you need to replace the entire disc. This entails shutting down the system to replace the rupture disc.

When installing the rupture disc, high care should be observed because a small scratch is enough to damage the entire rupture disc thereby affecting its performance. During installation, you should also look into the bolt torque as it can affect the disc burst pressure.

What are the different classifications of rupture discs?

There are three classifications of rupture discs: reverse-acting, forward-acting, and compact. Reverse acting rupture discs are also called compression loaded type disc. It is installed to reverse and open disc through a predetermined pattern of scoring.

A forward-acting rupture disc, on the other hand, is also called tension loaded type disc. This works when the process pressure increases. When the allowable operating pressure increases, the rupture disc will grow as well. Finally, a compact rupture disc is a small pipe size of forward-acting or reverse-acting discs.

What to remember when securing rupture discs?

When securing rupture discs, you have to remember the dimension, burst pressure, and burst tolerance. Dimension refers to the diameter of the discs as specified in the NPS (Nominal Pipe Size) or European context.

The burst pressure, on the other hand, refers to the pressure at which the disc will open. It should be selected in a manner that it opens before any system damage. Finally, the burst tolerance defines the tolerance which will open the rupture disc.

Final words

Without a doubt, rupture discs are a practical option for vessel and pipeline protection. Together with other components, it can benefit your industrial plant in terms of performance and safety.